모든 제품

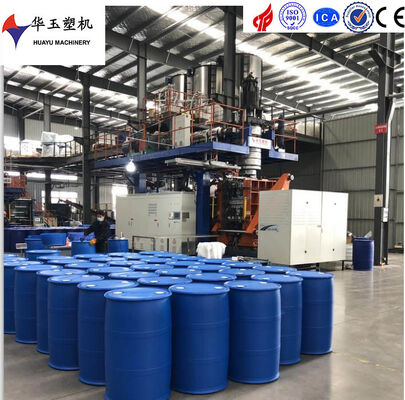

250L Capacity Double-Ring Drum Blow Molding Machine with 30:1 L/D Ratio and Energy-Saving Operation

무료 샘플과 쿠폰을 받으려면 연락하세요.

WhatsApp:0086 18588475571

웨이 채팅: 0086 18588475571

스카이프: sales10@aixton.com

걱정이 있으시면 24시간 온라인 서비스를 제공합니다.

x제품 상세 정보

| 나사 직경 | 150MM | L/D | 30 : 1 |

|---|---|---|---|

| 나사 재료 | 38CrMoAlA, 질화 | 산출 | 30PCS/시간 |

| 공기 공급 | 0.8×6(MPa×분당 입방미터) | 총 전력 | 324.5KW |

| 평균 에너지 소비 (AEC) | 시간당 약 180kw | ||

| 강조하다 | 250L Capacity Drum Blow Molding Machine,30:1 L/D Ratio Blow Molding Apparatus,Energy-Saving Operation Double-Ring Drum Blow Molder |

||

제품 설명

250L 1-Layer Double-Ring Drum Blow Molding Machine

Key Advantages

- High Production Efficiency: Fast cycle times and continuous molding capability deliver 50+ 250L double-ring drums per hour, significantly boosting production output for large-scale manufacturing.

- Precision Molding Performance: Advanced servo control system and precise die head design ensure uniform wall thickness and consistent double-ring structural dimensions, meeting strict industrial standards.

- Energy-Saving Operation: Energy-efficient motor and heat recovery technology reduce power consumption by 15-20% compared to traditional machines, cutting long-term operational costs.

- User-Friendly Operation: Intuitive touch screen HMI with pre-set molding parameters minimizes training time and simplifies daily production adjustments.

- Durable Equipment Build: High-strength steel frame and wear-resistant components provide a service life of over 10 years with minimal maintenance.

- Versatile Compatibility: Optimized for 250L 1-layer double-ring drums but adjustable for different plastic materials (HDPE/PP) and similar-sized barrel products.

- Stable Double-Ring Forming: Dedicated mold and air pressure control unit ensure rings have strong load-bearing capacity without deformation, meeting stacking and transportation requirements.

- Low Material Waste: Precision material feeding system and optimized parison control reduce plastic scrap rate to less than 3%, lowering raw material costs.

Energy Configuration Specifications

| Component | Specification |

|---|---|

| Extruder Driving Power | 160kw Siemens Independent Air Cooler |

| Hydraulic Main System Motor Power | 35.6KW Huichuan Servo Motor |

| Wall Thickness Control Motor Power | 7.5 KW |

| Heating Power of Extrusion System | 7 pcs * 7KW/pc |

| Power of Die Heating | 7 pcs * 6KW/pc |

| Air Supply | 0.8*6 (MPa * Cubic meter per minute) |

| Cooling Water Consumption | 0.3*20°*30 (MPa * degree * Cubic meter per hour) |

| Total Power | 324.5KW |

| Average Energy Consumption (AEC) | Approximately 180kw per hour |

This industrial blow molding machine is engineered for high-volume production of 250L double-ring drums, combining precision engineering with energy-efficient operation for optimal manufacturing performance.